Introducing

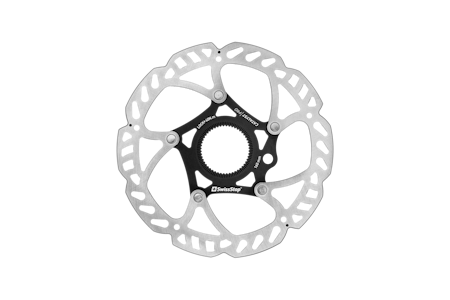

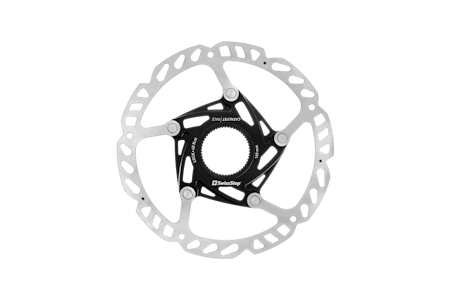

The Catalyst Family of Disc Brake Rotors

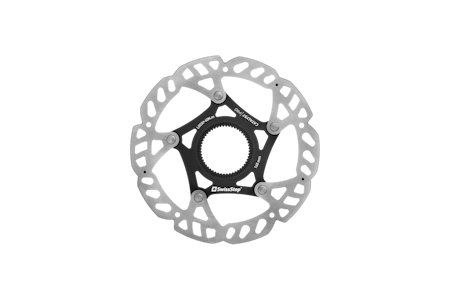

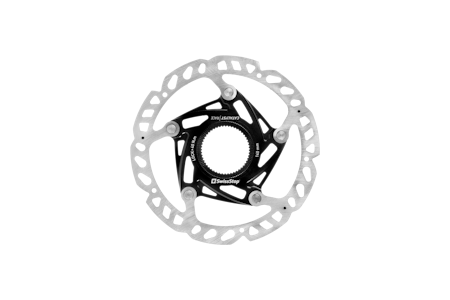

Power and Durability

powerful braking and high durability, available in five sizes for applications including road, cyclocross, cross country, downhill and e-bike

Accepted by the UCI for road competition

the perimeter edge of the Catalyst brake rotor does not contain any 90 degree edges

Wear out indicators

small divots on the surface show when it is time to replace the rotor

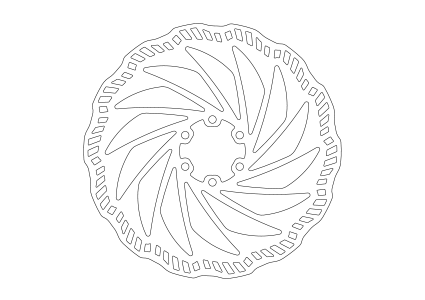

1. DESIGN AND MODELLING

2015 — Development Begins

The SwissStop engineering team conducted a series of laboratory tests on bicycle brake disc rotors. Next, they created digital models of these rotors and simulated the same test environments using advanced software. A comparison of the data verified that the simulations were accurate and effective, giving the engineers confidence to proceed with creating an array of digital prototypes to thoroughly test and evaluate.

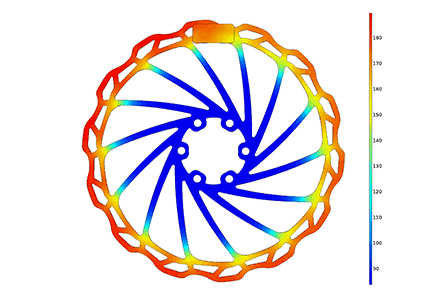

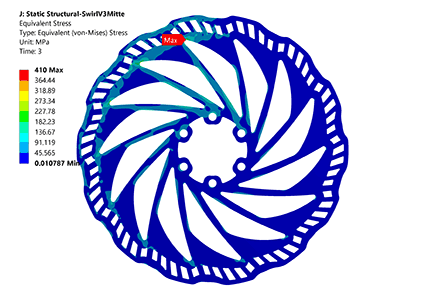

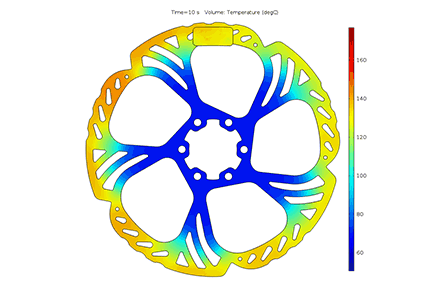

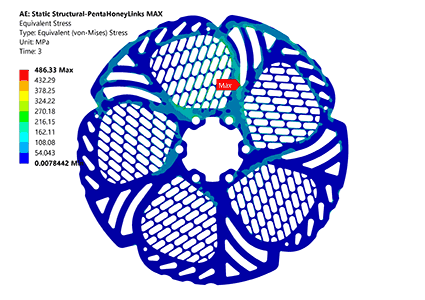

2. HEAT AND STRUCTURE SIMULATIONS

Heat transfer within the design concepts was studied extensively using engineering simulation software. The relationships between convection, radiation, surface area and weight were used to determine the optimal design to maximize heat dissipation and strength while minimizing weight. The structure of each design was evaluated under braking forces ranging from typical hand pressure up to theoretical maximums. Critical pressure points in the structure were identified in order to maximize the strength and stiffness of the rotor.

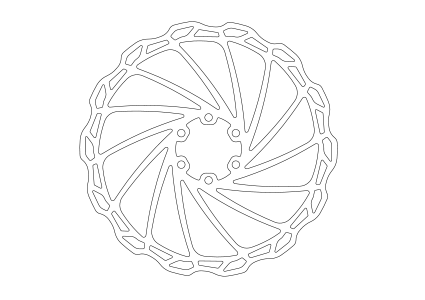

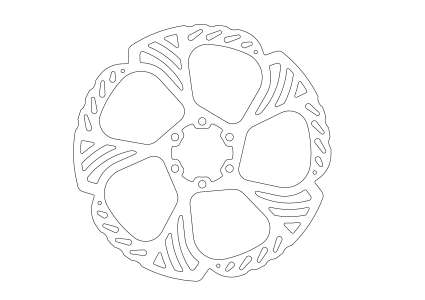

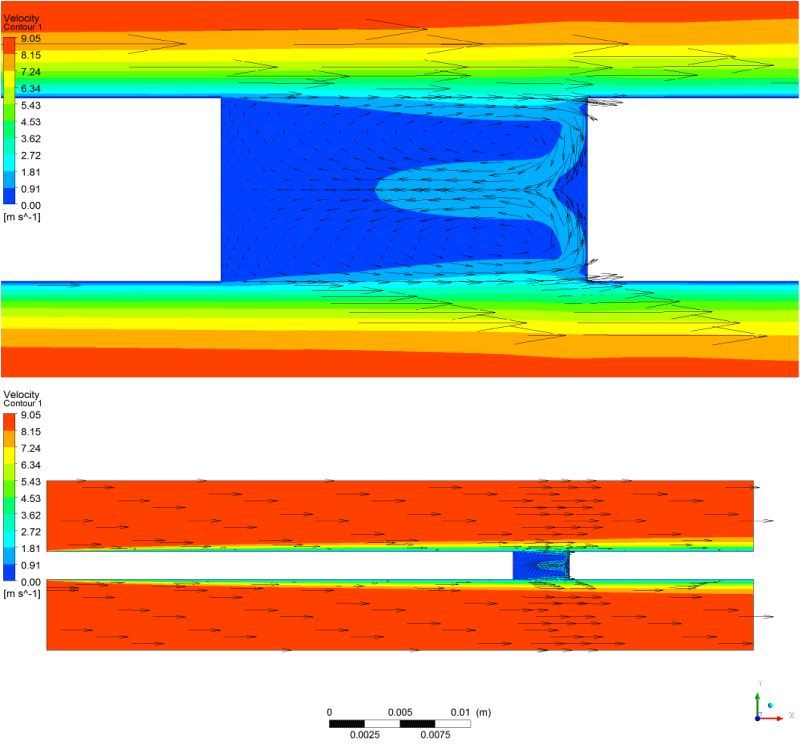

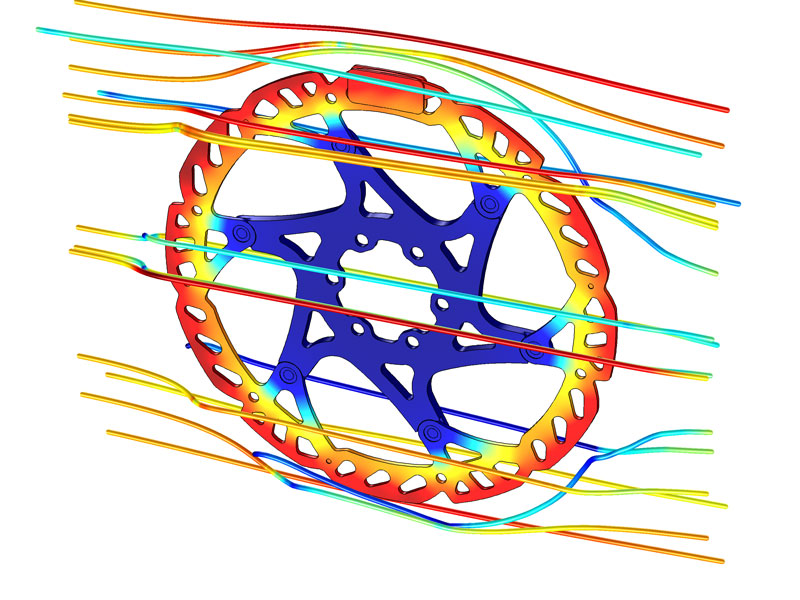

3. AIRFLOW ANALYSIS

Computational fluid dynamics (CFD) simulations were performed to study airflow over the surface of the rotor and through the cut-outs. A variety of profiles were tested to determine the effects of asymmetrical holes and optimize the cooling effect of airflow over the surfaces.

Thermodynamic simulations, structural analysis and fluid dynamic visualizations were conducted in collaboration with the Institute for Energy Technology at OST University of Applied Science.

4. FINAL DESIGN

2016 — First Catalyst Model Announced

The performance of the Catalyst design was confirmed with further digital modelling and thermodynamic simulation studies. Following this phase, physical prototypes were produced for extensive lab and field testing. The process validated the design. Upon completion, the first Catalyst model, featuring a 7075T6 aluminum alloy spider and SUS410 stainless steel brake track, was formally announced.

2017-2020 — Cyclists of all types, including top MTB, Cyclocross and UCI World Tour road athletes, discover the power, durability and reliability of Catalyst rotors.

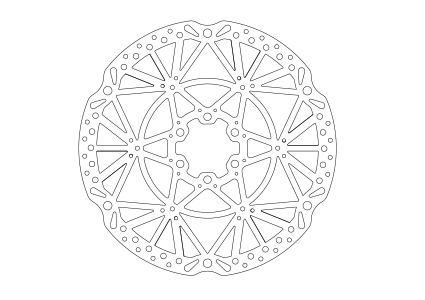

2021 — The SwissStop engineering team applied the Catalyst design concept to new rotor models, focusing on the requirements of ever-more specific applications that riders encounter. New one-piece and race-optimized two-piece models are developed.

ENGINEERED TO SET A NEW STANDARD

- OPTIMUM HEAT DISSIPATION

- RELIABLE PERFORMANCE FROM CYCLOCROSS TO DOWNHILL

- HIGH DURABILITY, EVEN IN THE TOUGHEST CONDITIONS